Sensor with crossed anisotropies, medium field sensor, automotive applications

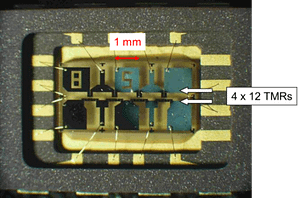

The team was awarded the Yves Rocard Prize in 2010 from the French Physical Society for the invention and the technological development of a new generation of ABS magnetic sensors for the NTN-SNR company, the team was awarded the Yves Rocard Prize in 2010 from the French Physical Society. The latter relies on the expertise of the team in terms of nanomagnetism for the development of a new sensitive layer but also in terms of tunnel junctions. Compared with conventional Hall sensors, the developed TMR sensors have a power consumption 1000 times lower and a greater sensitivity to long distance that will allow the measure the speed of rotation of a workpiece, in particular through a motor housing.

Fluxgate sensor using magnetoresistive detection, low field sensor

Magnetic field sensors of ‘Flux-gate’ type, which use the hysteresis properties of magnetic materials are known for their high resolution and accuracy and low manufacturing cost. However, these sensors are not suitable for miniaturization. To achieve microsenseurs, sensors based on the giant magnetoresistance present the best features. Indeed, the magneto-resistive properties are almost independent of the size of the sensitive element and strong magneto-resistance can be obtained in submicron elements. We combined the advantages of both sensors by replacing the sensor coil of the ‘Flux-gate’ by a magnetoresistive sensor with its hysteretic response. We were able to stabilize in a tunnel junction two magnetic layers with coercive field less than 30 Oe and a first demonstration of the functionality of the sensor could be achieved with a magnetoresistive tunnel junction. Moreover, we could show that the concept could be extended to a two-dimensional measurement of the magnetic field with a single tunnel junction.

Sensor with crossed anisotropies, high field sensor

An extension of the previous study consists to increase the anisotropy of the sensitive layer in order to allow a measurement of the intensity of magnetic field in a wider range. This is possible using the demagnetizing field which is a natural anisotropy in thin films. The latter can reach a value higher than 2 Tesla. While the sensitive layer has a planar magnetization, the reference layer has a perpendicular magnetization, parallel to the direction of application of the field to be detected. We observe a linear variation of the tunnel junction resistance with the applied field that can be used in a linear field sensor. Its response saturates for an applied field around 2T.

Magnetic SAW Sensors

SAW devices, whose principle is based on the propagation of surface acoustic waves are known since the 60’s and are used primarily as a filter, resonator or delay line in communication systems. They are also used for the production of sensors: temperature sensor, pressure, etc. Recently, we have incorporated magnetic material into the device and modeled their response. By varying the magnetic properties of the materials, we were able to achieve magnetic field adjustable sensitivity sensors.

Biosensor

Several biosensor applications are based on the functionalization of magnetic nano beads and on their spatial localization. In our study, magnetic domain walls in nano-sized objects are generating at its vicinity a magnetic field which can be used to trap magnetic nanobeads. We used innovating design to increase both the sensitivity and the portability (autonomy) of an existing biosensor. The magnetic trap (domain walls) will be activated (created) or deactivated (annihilated) by use of a permanent magnet which avoids the use of an external power supply. Moreover the magnetic trap will be situated at the end of on optical fiber. This means that with the new design most of the section of the optical fiber will host the photons sources. This will naturally increase the sensor sensitivity.

CMOS integration

The integration in post-processing of magnetic nanostructures onto CMOS circuits is also a promising approach for the production of sensors providing performance comparable to flow-gate but integrated. Indeed, a fluxgate magnetic micro-sensor using Hall sensors instead of measuring coils commonly used in this type of magnetometer allows to integrate the principle of fluxgate while eliminating the problem of coupling between the core and the planar measuring coil. A behavioral model of the sensitive structure was developed by simulation to validate the measurement principle. The first experimental results are encouraging but show that a post-polishing process is necessary before the deposition of the magnetic core. In this project, the core is made by sputtering deposition and lift off of a soft layer magnetic layer made of permalloy or cobalt.